SX Static Mixer

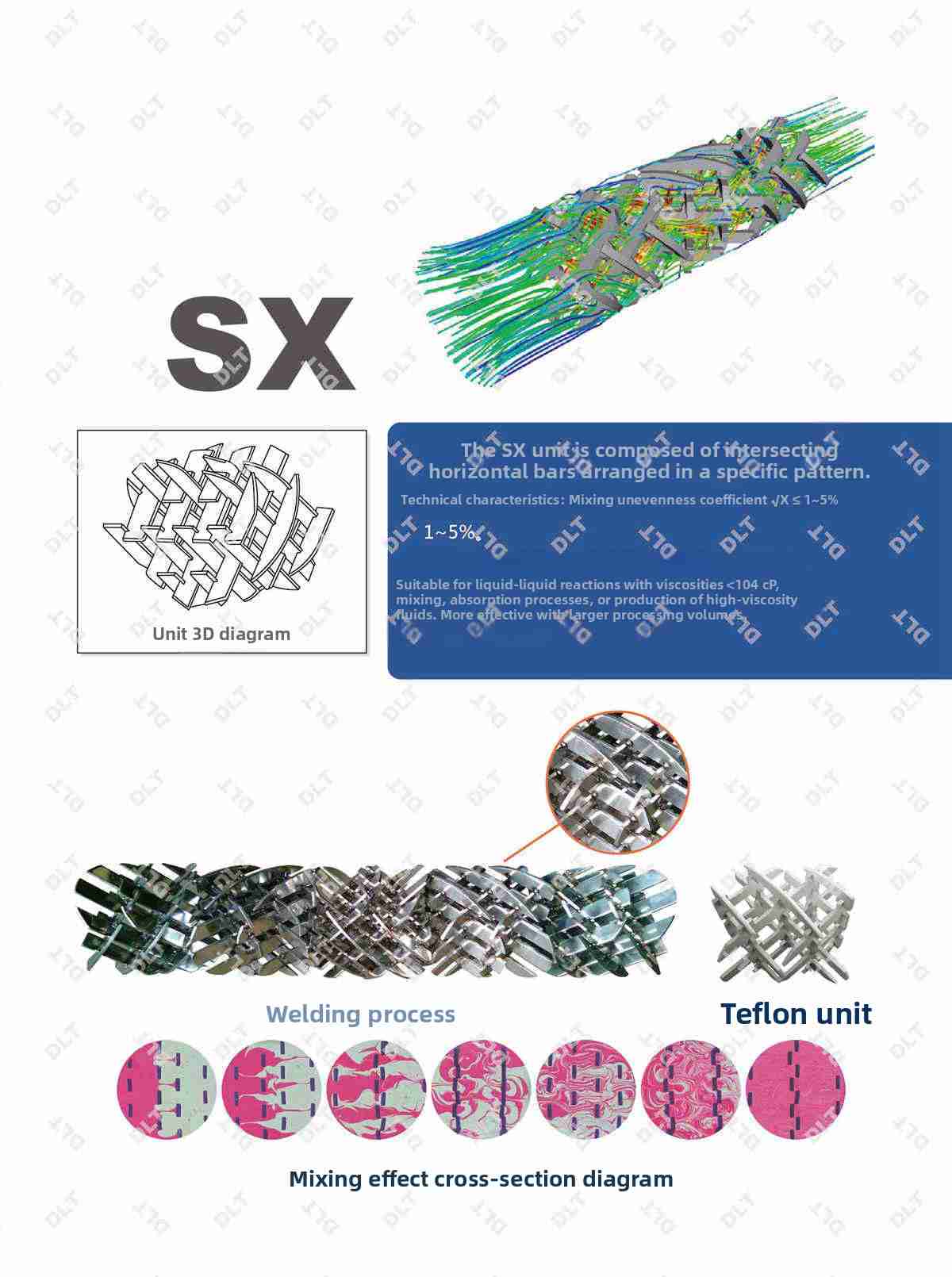

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersecting cross-bars that systematically form multiple X-shaped units along the flow path, creating an exceptionally effective mixing environment for demanding industrial applications.

Innovative Structural Design

At the core of the SX Static Mixer's effectiveness is its distinctive construction. The mixing elements consist of precisely arranged intersecting cross-bars that form repeated X-patterned units throughout the tubular housing. This configuration creates a complex network of flow channels that ensure thorough fluid reorganization with each successive element. The geometric pattern is mathematically optimized to provide maximum interfacial area generation while maintaining manageable pressure drop characteristics.

Technical Performance Specifications

The SX Static Mixer demonstrates exceptional performance metrics, particularly evidenced by its mixing inhomogeneity coefficient of √6X ≤ 1.25%. This quantitative measure confirms the unit's ability to achieve near-perfect homogeneity in even the most challenging mixing scenarios. The mixer is specifically designed for fluids with viscosity up to 10,000 cP (10,000 mPa·s), making it ideally suited for medium to high viscosity applications that typically challenge conventional mixing technologies.

Application Excellence

The SX Static Mixer excels in multiple demanding industrial processes:

Liquid-Liquid Reactions: Provides intense mixing for viscous chemical reactions requiring precise stoichiometric control

Polymer Processing: Ideal for polymerization reactions and polymer blending operations where viscosity increases progressively

Absorption Processes: Effective for gas-liquid absorption in viscous media

High-Viscosity Blending: Superior performance in mixing applications involving resins, adhesives, and elastomers

Enhanced Performance at Scale

A notable characteristic of the SX Static Mixer is its improved effectiveness at higher processing rates. The design demonstrates optimal performance when handling substantial volumetric flow rates, making it particularly valuable for:

Continuous production processes

Large-scale industrial operations

High-capacity manufacturing lines

Bulk chemical processing

Operational Advantages

The SX Static Mixer provides significant benefits over alternative mixing technologies:

Superior Mixing Efficiency: Achieves excellent homogeneity in viscous fluids without mechanical moving parts

Reduced Energy Consumption: Optimized geometry minimizes pressure drop while maximizing mixing effectiveness

Low Maintenance Requirements: Simple, robust construction eliminates need for rotating components or seals

Process Flexibility: Handles wide viscosity ranges and flow rate variations without performance degradation

Easy Integration: Standard dimensions facilitate simple installation in existing piping systems

Technical Superiority

The X-shaped unit configuration creates a multi-directional mixing action that ensures complete fluid reorganization. Each successive element:

Divides the main flow stream into multiple substreams

Creates intense radial mixing components

Generates interfacial area exponentially

Ensures complete cross-sectional homogeneity

Material Compatibility

SX Static Mixers are available in various materials including:

316/304 Stainless Steel for general applications

Hastelloy for corrosive environments

Specialized coatings for abrasive services

FDA-compliant materials for pharmaceutical and food applications

Quality Assurance and Validation

Every SX Static Mixer undergoes rigorous quality control procedures including:

Computational Fluid Dynamics (CFD) analysis for performance verification

Material certification and traceability

Dimensional validation and pressure testing

Process-specific performance validation

The SX Static Mixer represents an optimal solution for demanding mixing applications involving viscous fluids. Its unique X-bar configuration, proven performance characteristics, and reliability make it the preferred choice for industries requiring precise, efficient mixing of medium to high viscosity materials. Whether for polymer production, specialty chemical manufacturing, or large-scale processing operations, the SX Static Mixer delivers consistent, reproducible results while reducing operational costs and maintenance requirements.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...