SL Static Mixer

The SL Static Mixer is a high-performance static mixing solution engineered to handle the most demanding mixing challenges in industries involving viscous fluids, polymers, and multi-phase media. Its unique single X-shaped unit design, formed by systematically intersecting cross-bars, ensures efficient mixing, heat transfer, and reaction enhancement for processes with viscosities up to 10⁶ cP.

Innovative Design and Working Principle

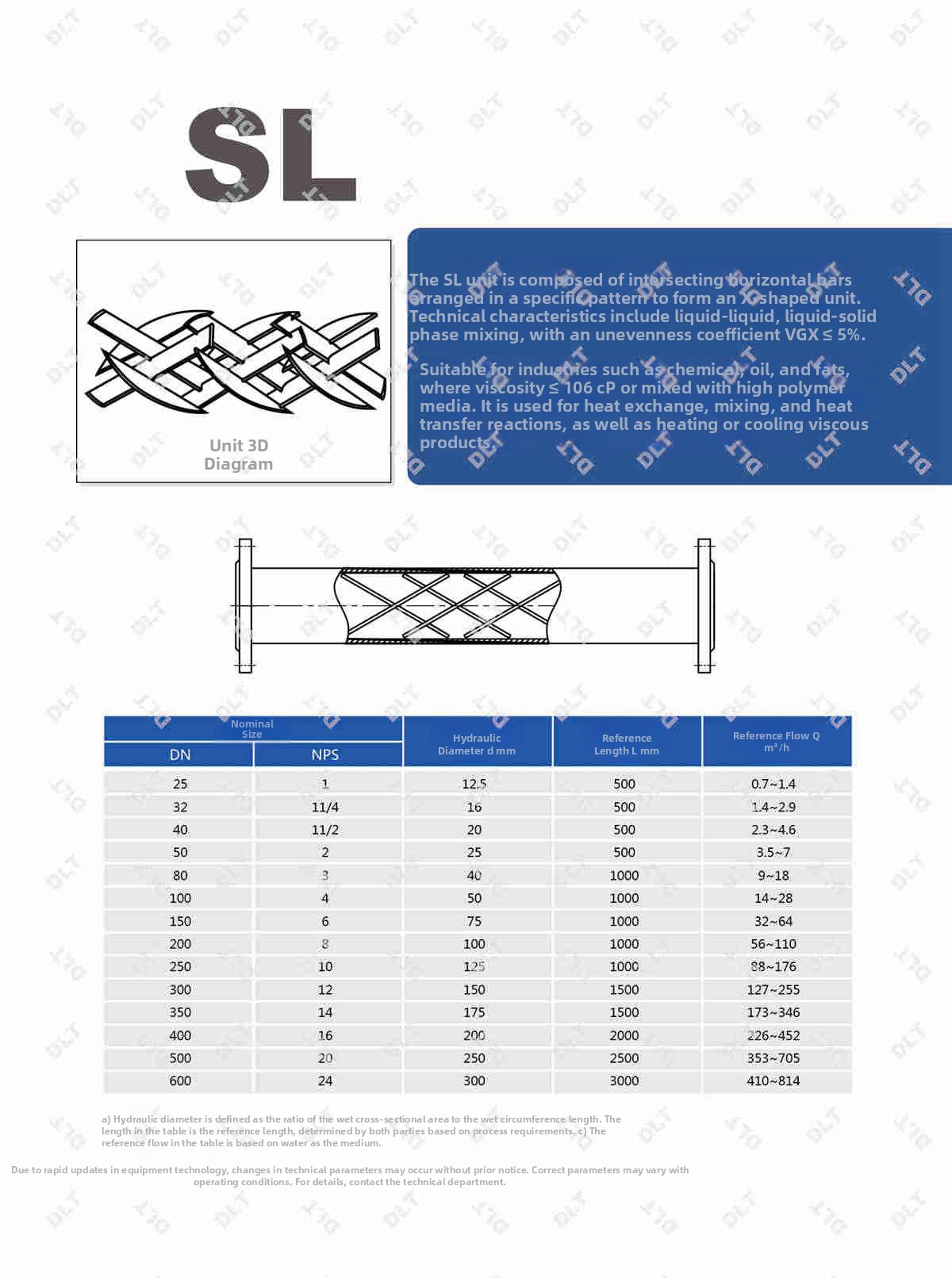

Single X-Shaped Unit Structure: Each SL unit consists of intersecting cross-bars arranged in a precise geometric pattern to create repeated X-shaped modules. This design splits, shears, and recombines fluid streams, ensuring rapid homogenization.

Multi-Functionality: Performs simultaneous mixing, heat transfer, and reaction operations, making it ideal for applications requiring combined unit processes.

Optimized Flow Paths: The structured X-shaped geometry enhances radial mixing while minimizing dead zones, ensuring uniform treatment of all fluid elements.

Technical Specifications

Mixing Phases: Liquid-Liquid, Liquid-Solid

Inhomogeneity Coefficient: √σX ≤ 5%

Viscosity Range: Suitable for media up to 10⁶ cP (1,000,000 mPa·s)

Applications: Mixing, heat transfer, reaction enhancement, heating/cooling of viscous products.

Key Applications

Chemical Industry:

Homogenization of high-viscosity reactants.

Polymerization processes with evolving viscosities.

Multi-phase mixing with solid catalysts or additives.

Petroleum and Refining:

Blending of heavy crude oils and additives.

Desulfurization and catalytic reaction enhancement.

Fat and Oil Processing:

Mixing and heat transfer in hydrogenation processes.

Cooling/heating of viscous edible oils and fats.

Polymer and Synthetic Materials:

Melt blending and devolatilization.

Reactive extrusion and compounding.

Heat Transfer Applications:

Serving as a static heat exchanger for heating/cooling viscous fluids.

Enhancing heat transfer efficiency in jacketed pipelines.

Advantages

Exceptional Viscosity Handling: Effectively processes fluids up to 1 million cP, including polymer melts and slurries.

Dual Functionality: Combines mixing and heat transfer in a single unit, reducing equipment footprint and costs.

High Mixing Efficiency: Achieves inhomogeneity coefficients ≤5% even for challenging liquid-solid systems.

Low Maintenance: No moving parts ensure reliability and reduce operational downtime.

Customizable Materials: Constructed in 304 SS, 316L, duplex steel, or other alloys to suit corrosive or abrasive environments.

Operational Flexibility

Scalable Design: From lab-scale prototypes to full industrial pipelines.

Adaptable Configuration: Units can be grouped or spaced to meet specific process requirements (e.g., residence time, shear sensitivity).

Integration with Heating/Cooling Jackets: Ideal for thermoregulated processes such as polymerization, crystallization, or viscosity modification.

Why Choose the SL Static Mixer?

Proven Performance: Trusted in industries where viscosity, mixing, and heat transfer are critical.

Energy Efficiency: Utilizes pipeline pressure for mixing, eliminating external energy input.

Versatility: Suitable for continuous processes in chemicals, petroleum, polymers, and food processing.

Technical Support: Custom-engineered solutions based on computational fluid dynamics (CFD) and process simulations.

The SL Static Mixer is the ultimate solution for complex processes involving high viscosity, multi-phase media, and combined mixing/heat transfer operations. Its robust design, efficiency, and adaptability make it indispensable for industries striving to optimize productivity and product quality. For detailed engineering support and parameter-specific recommendations, contact our technical team.

Note: Specifications may be subject to change due to continuous product improvements. Refer to the latest technical documentation for accurate information.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...