SK Static Mixer

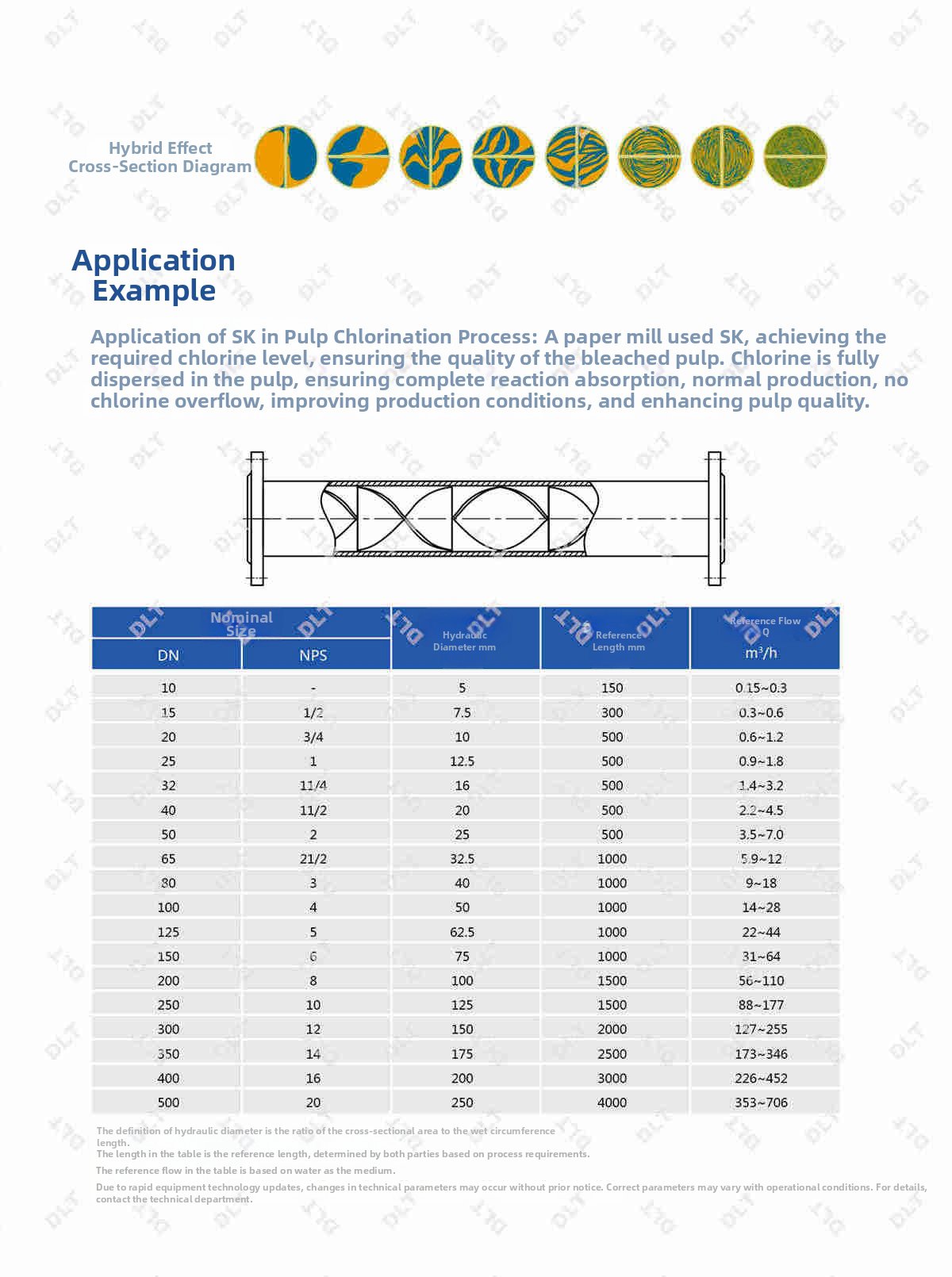

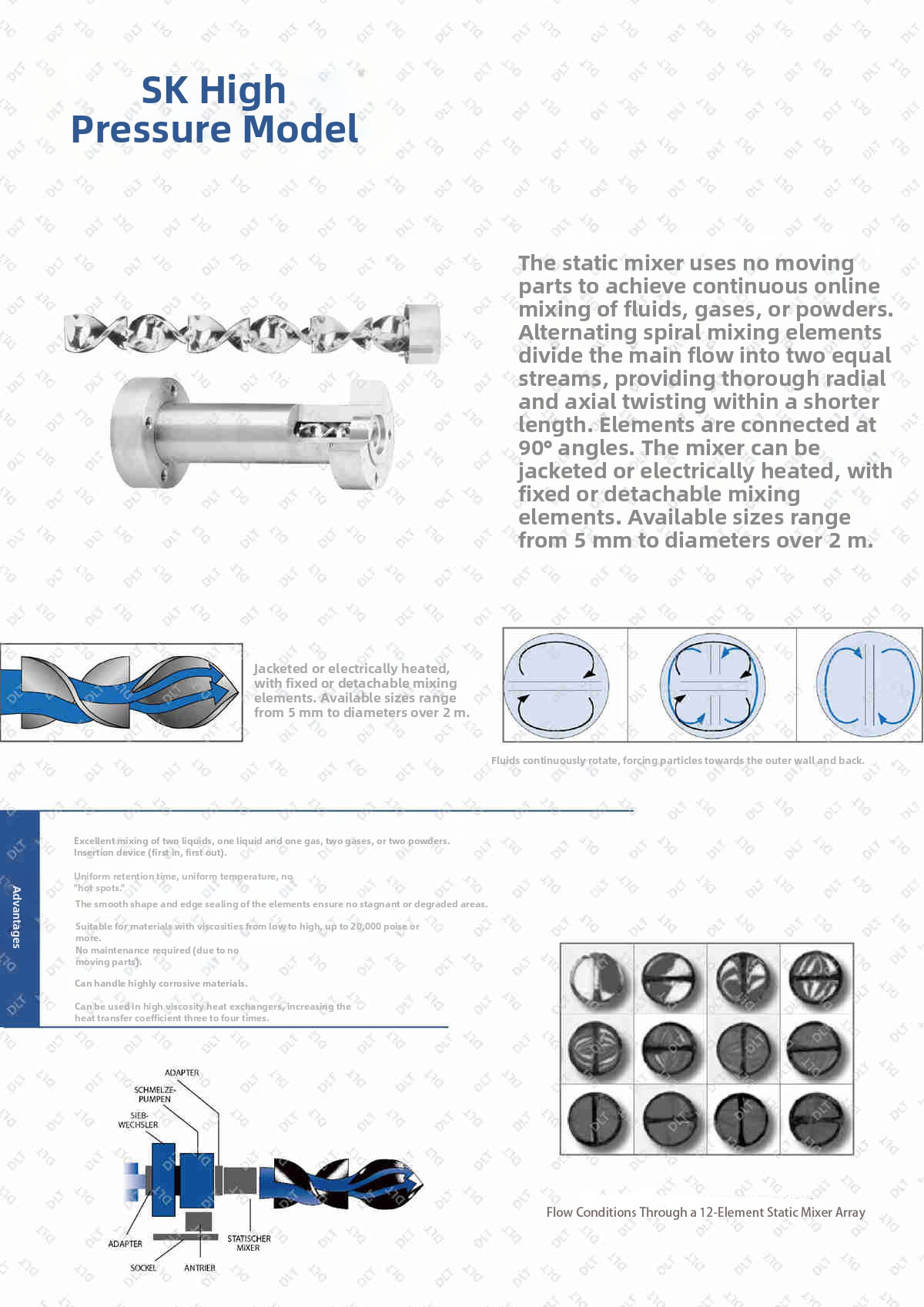

The SK Static Mixer is a highly efficient motionless mixing device constructed by welding together a series of left- and right-hand twisted spiral elements within a single channel. This design ensures precise and homogeneous blending of fluids without the need for moving parts, making it a reliable and maintenance-free solution for a wide range of industrial processes.

Technical Performance:

Maximum Degree of Dispersion: ≤ 10 µm

Coefficient of Non-uniformity (for liquid-liquid, liquid-solid phases): √σₓ ≤ 5%

These performance metrics highlight the mixer’s exceptional ability to achieve fine dispersion and uniform distribution of phases, even in challenging applications.

Applications:

The SK Static Mixer is widely used across multiple industries due to its versatility and efficiency. Key sectors and processes include:

Chemical, Petrochemical, and Refining: Mixing, reaction, extraction, and absorption

Pharmaceutical and Food: Blending of ingredients, emulsification, and heat transfer

Environmental Engineering: Wastewater treatment and gas scrubbing

Plastics and Fine Chemicals: Polymerization, coloring, and injection molding

Synthetic Fibers and Mineral Processing: Homogenization and mass/heat transfer

It is particularly suitable for applications involving moderate to low flow rates, fluids containing impurities, or highly viscous media with viscosities up to 10⁶ cP.

The robust design and superior mixing capability of the SK Static Mixer make it an ideal choice for enhancing process efficiency and product quality in diverse industrial operations.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...