SV Static Mixer

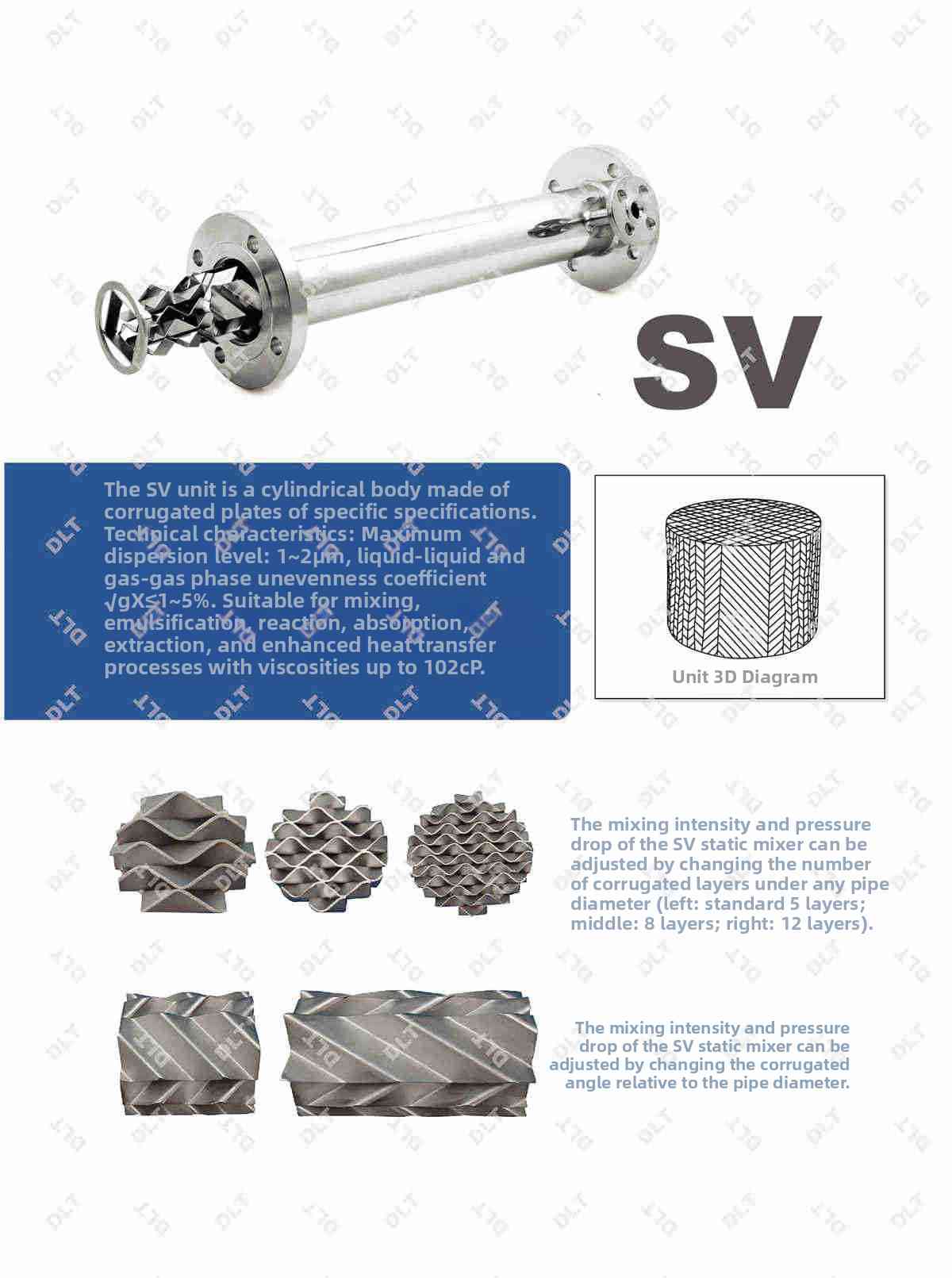

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a wide range of applications, particularly in liquid-liquid, gas-gas, and liquid-gas processing systems.

Core Technology and Design

The SV mixing unit consists of precision-engineered corrugated plates arranged in a cylindrical formation within the housing. This design generates complex flow patterns that ensure thorough fluid interaction and distribution. The corrugated plates create multiple contact points and flow channels, promoting intense mixing through a combination of division, rotation, and recombination mechanisms.

Technical Specifications

Maximum Dispersion Degree: 1-2 μm

Liquid-Liquid & Gas-Gas Inhomogeneity Coefficient: √σX ≤ 1-5%

Viscosity Range: Suitable for fluids up to 10² cP (100 mPa·s)

Applications: Mixing, emulsification, reaction, absorption, extraction, and enhanced heat transfer processes

Adjustable Performance Parameters

A key innovation of the SV Static Mixer is its customizable performance characteristics:

Corrugation Layer Adjustment

The mixing intensity and pressure drop can be precisely tuned by varying the number of corrugated layers within the same pipe diameter:Standard Configuration: 5 layers (moderate mixing, lower pressure drop)

Enhanced Mixing: 8 layers (increased intensity, moderate pressure drop)

High-Intensity Mixing: 12 layers (maximum mixing, higher pressure drop)

Corrugation Angle Optimization

Additional performance tuning is achieved by adjusting the corrugation angle relative to the pipe diameter:Shallow angles provide gentler mixing with lower pressure drop

Steeper angles create more intense mixing with higher energy consumption

Optimal angles are selected based on specific process requirements

Application Versatility

The SV Static Mixer excels in numerous processing scenarios:

Liquid-Liquid Systems: Emulsification, extraction, and chemical reactions

Gas-Gas Applications: Blending of gases with different densities and properties

Liquid-Gas Processes: Absorption, stripping, and aeration

Heat Transfer Enhancement: Improved thermal exchange in various media

Performance Characteristics

Superior Dispersion: Achieves micron-level dispersion quality (1-2 μm)

Exceptional Homogeneity: Maintains consistent mixing quality with inhomogeneity coefficients as low as 1%

Broad Viscosity Handling: Effective with fluids up to 100 cP

Flexible Configuration: Adaptable to various process requirements through layer and angle adjustments

Operational Advantages

No Moving Parts: Maintenance-free operation with no mechanical components

Easy Installation: Simple integration into existing piping systems

Scalable Design: Consistent performance from laboratory to industrial scale

Material Compatibility: Available in stainless steel, specialty alloys, and plastics

Clean-in-Place Capability: Suitable for sanitary applications

Industry Applications

Chemical Processing: Reaction intensification and solvent extraction

Pharmaceuticals: Emulsion preparation and API synthesis

Food & Beverage: Mixing of ingredients and flavor homogenization

Water Treatment: Chemical dosing and gas absorption

Petrochemical: Gas blending and process intensification

Technical Customization

The SV Static Mixer offers unprecedented flexibility through:

Layer count optimization for specific process needs

Corrugation angle adjustment for precise performance tuning

Material selection for compatibility with process media

Diameter variations to match flow rate requirements

Quality and Reliability

CFD-optimized design for maximum efficiency

Rigorous quality control and testing

Performance validation for each application

Compliance with international standards

The SV Static Mixer represents the perfect combination of innovative design and practical engineering, offering processors unparalleled flexibility in achieving precise mixing results across a broad spectrum of applications. Its adjustable parameters and proven performance make it an ideal solution for industries requiring reliable, efficient, and customizable mixing technology.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...