SO Static Mixer

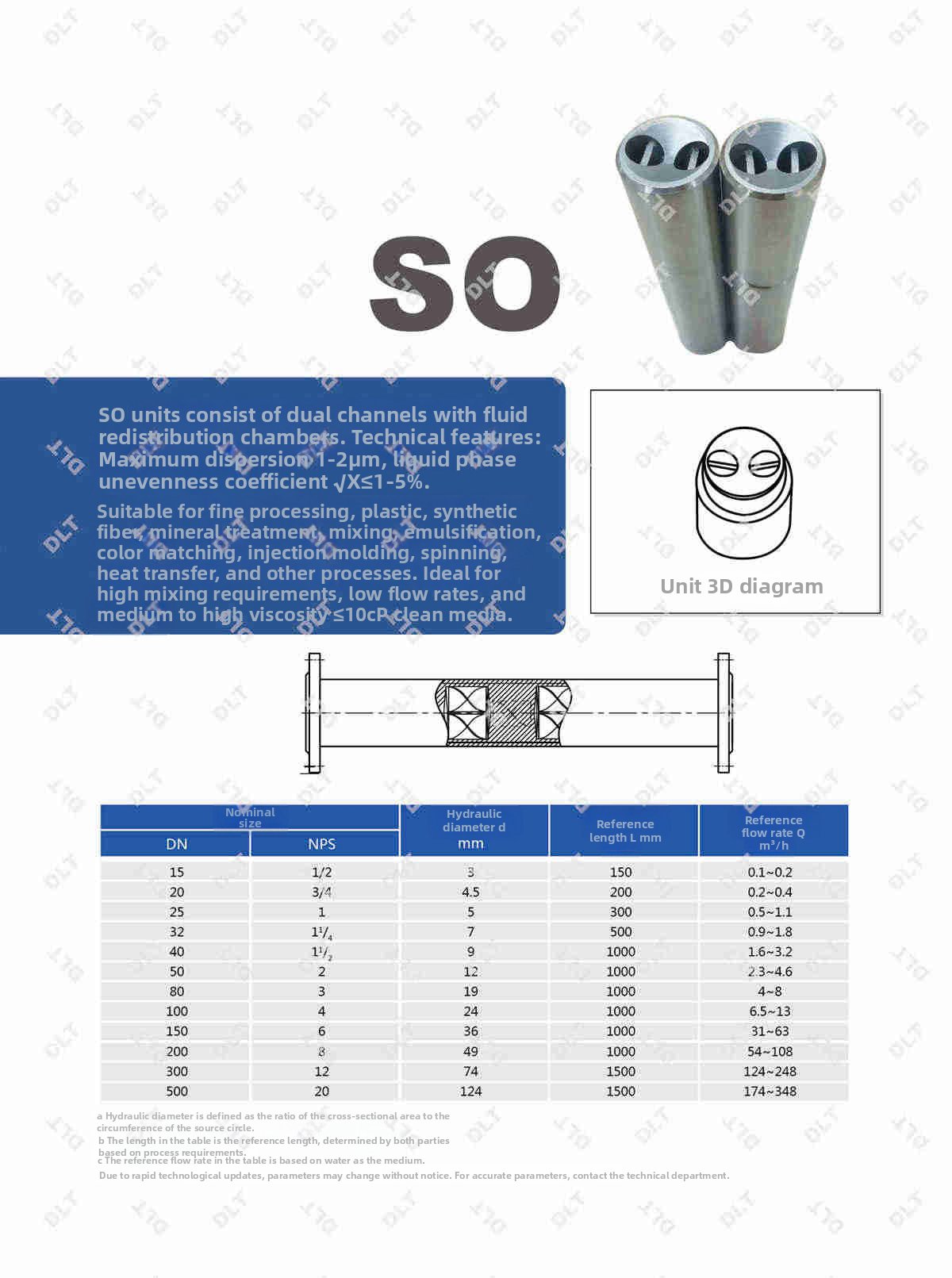

The SO Static Mixer is an engineered solution designed for high-precision mixing processes where homogeneity, efficiency, and reliability are critical. Its unique dual-channel configuration, combined with fluid redistribution chambers between units, ensures exceptional performance in handling medium-to-high-viscosity clean media (≤10⁵ cP) with low flow rates and stringent mixing requirements.

Innovative Design and Working Principle

Dual-Channel Units: Each SO unit features two precisely designed flow channels that split and redirect the fluid stream, promoting intense radial mixing and eliminating concentration gradients.

Fluid Redistribution Chambers: Strategically placed between units, these chambers ensure complete fluid reorganization before entering the next mixing stage, enhancing homogeneity and preventing bypassing.

Hydraulic Diameter Optimization: The mixer’s hydraulic diameter (defined as four times the flow cross-sectional area divided by the wetted perimeter) is optimized to balance pressure drop and mixing efficiency for viscous fluids.

Technical Specifications

Maximum Dispersion Degree: 1–2 mm

Liquid-Liquid Inhomogeneity Coefficient: √σX ≤ 1–5%

Viscosity Range: Ideal for media up to 10⁵ cP (100,000 mPa·s)

Reference Length (L): Customizable based on process requirements (agreed upon between supplier and customer).

Reference Flow Rates: Based on water as the medium; actual values vary with fluid properties and operational conditions.

Key Applications

The SO Static Mixer excels in industries demanding ultra-precise mixing and processing:

Fine Chemicals: Homogenization of high-value reactants and solvents.

Plastics and Polymers: Uniform coloring, additive blending, and melt homogenization.

Synthetic Fibers: Precous dosing and mixing for spinning and extrusion processes.

Mining and Metallurgy: Efficient mixing of reagents and slurries.

Advanced Processes: Emulsification, chemical reactions, heat transfer enhancement, and injection molding.

Advantages

Superior Mixing for Viscous Media: Achieves unmatched homogeneity in high-viscosity fluids with minimal energy input.

Compact and Scalable: Suitable for low-flow applications without compromising performance.

Zero Moving Parts: Maintenance-free operation with no risk of mechanical failure.

Customizable Geometry: Reference length () and hydraulic diameter are tailored to specific process needs.

Cleanability: Ideal for clean media; resistant to clogging and easy to sanitize.

Technical Notes

Hydraulic Diameter (): Defined as , optimized to minimize pressure drop while maximizing mixing efficiency.

Reference Length (): Determined collaboratively with customers based on process objectives (e.g., residence time, mixing intensity).

Flow Rates: Reference values provided for water; actual performance depends on fluid properties (viscosity, density) and operational conditions.

Dynamic Updates: Due to rapid technological advancements, specifications are subject to change. For accurate parameters, consult our technical team.

Why Choose the SO Static Mixer?

Precision Engineering: Dual-channel design and redistribution chambers ensure uniform mixing even at low flow rates.

Industry-Specific Solutions: Tailored for sectors like plastics, fibers, and fine chemicals where precision is non-negotiable.

Energy and Cost Savings: Static operation reduces energy consumption and maintenance costs.

Future-Proof Design: Continuous improvements ensure alignment with evolving industrial needs.

The SO Static Mixer sets a new standard for precision mixing in high-viscosity applications. Its innovative design, flexibility, and proven performance make it the ideal choice for industries where quality, efficiency, and reliability are paramount. For detailed technical specifications and process-specific recommendations, contact our engineering team today.

Note: Specifications are subject to change without prior notice due to ongoing product enhancements. Always refer to the latest technical documentation for accurate information.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...