HFB Static Mixer

The HFB Static Mixer represents the pinnacle of industrial mixing technology, combining superior static mixing performance with integrated heat exchange capabilities in a single, efficient unit. This innovative static mixer solution seamlessly integrates mixing elements with advanced thermal technology, creating an unparalleled system for simultaneous mixing and temperature control in chemical processing applications.

Superior Static Mixer Performance with Integrated Heat Transfer

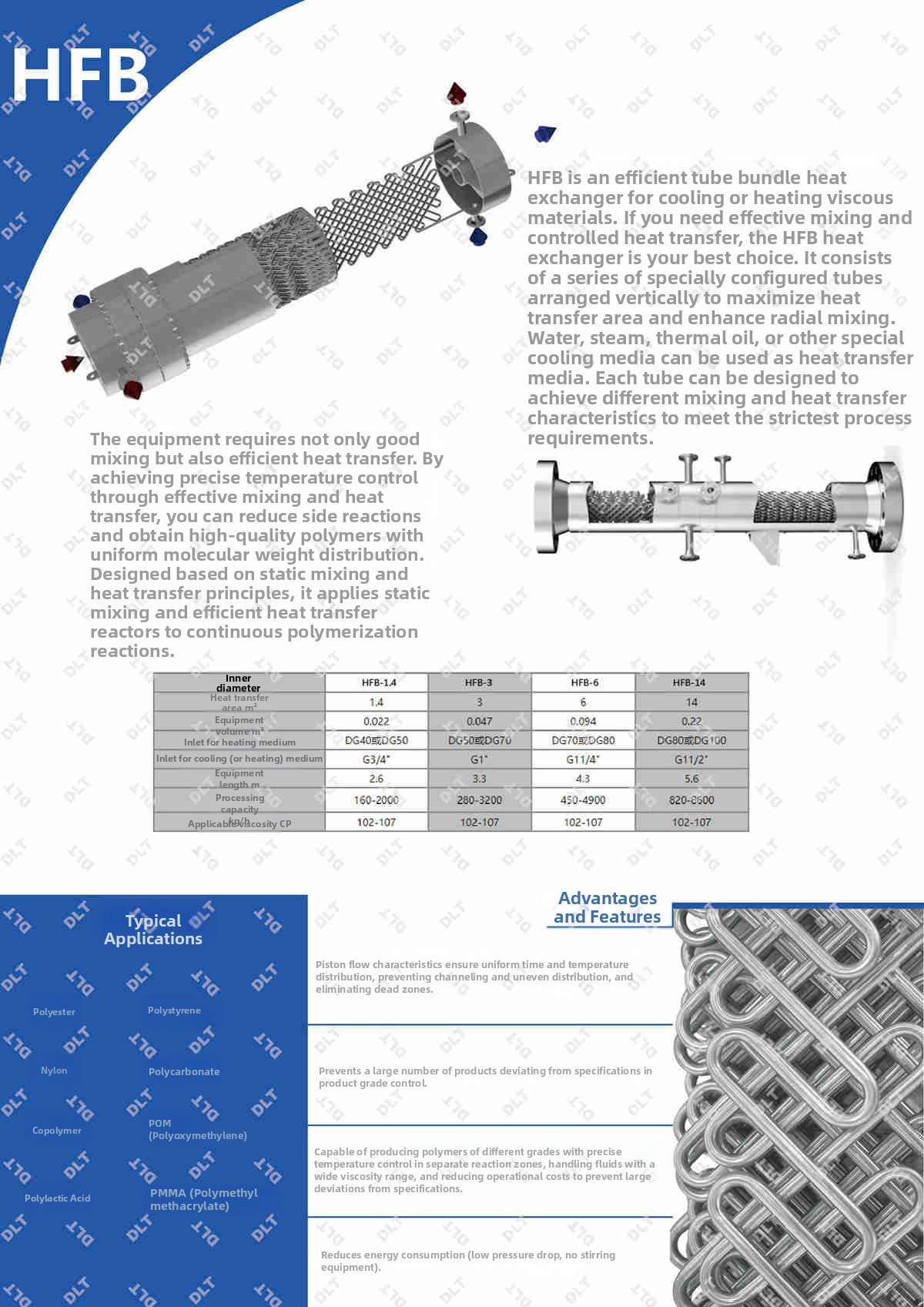

The HFB Static Mixer delivers exceptional mixing efficiency and heat transfer capacity, specifically engineered for challenging applications involving viscous materials, high-viscosity liquids, and complex chemical reactions. Unlike conventional static mixers, the HFB series incorporates advanced thermal exchange surfaces within its mixing structure, enabling precise temperature control and uniform thermal distribution throughout the mixing process.

Advanced Static Mixing Technology

Our static mixer technology features specially configured mixing elements that create optimal fluid manipulation and perfectly defined mixing effects across the entire cross-section. The innovative tube arrangement enhances radial mixing while providing extensive heat exchange surfaces. This dual functionality makes the HFB Static Mixer ideal for applications requiring:

Effective mixing with controlled heat transfer

Cooling or heating of viscous materials

Precise temperature management during chemical reactions

Uniform thermal distribution in high-viscosity applications

Multi-Media Heat Transfer Capabilities

The HFB Static Mixer supports various heat transfer media including water, steam, thermal oil, and specialized cooling fluids. Each mixing tube can be custom-designed to achieve specific mixing and heat transfer characteristics, ensuring optimal performance for even the most stringent process requirements. The vertical tube configuration maximizes heat transfer area while enhancing mixing efficiency through improved radial flow patterns.

Industry Applications

This advanced static mixing solution excels in numerous industrial applications including:

Chemical processing with simultaneous mixing and temperature control

High-viscosity liquid processing with thermal management requirements

Pharmaceutical manufacturing requiring precise thermal control

Food processing applications with sensitive temperature parameters

Polymer and resin production with exacting viscosity specifications

Performance Advantages

The HFB Static Mixer delivers unmatched benefits:

Exceptional heat transfer capacity combined with high mixing efficiency

Precise temperature control and even thermal distribution

Superior performance with viscous materials and complex fluids

Reduced energy consumption through optimized thermal exchange

Minimal maintenance requirements with no moving parts

Compact design that saves valuable production space

Customizable configurations for specific process requirements

Innovative Engineering Design

The HFB system consists of a series of specially configured tubes arranged vertically to maximize both heat transfer surface area and radial mixing efficiency. This innovative design ensures effective mixing and controlled heat transfer, making it the ideal choice for processes requiring simultaneous mixing and thermal management.

For operations requiring precise thermal control alongside thorough mixing efficiency, the HFB Static Mixer delivers unparalleled performance, reliability, and results. Experience the future of industrial mixing technology with our advanced static mixer solutions, designed to meet the strictest process requirements in today's most demanding industrial applications.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...