HFA Static Mixer

The HFA Static Mixer represents cutting-edge static mixing technology specifically engineered for high-temperature industrial applications and demanding processes such as polymer reactions, degassing operations, and continuous processing in food and pharmaceutical industries. This advanced static mixer combines superior mixing performance with exceptional thermal transfer capabilities, making it the ideal solution for applications requiring precise temperature control and efficient material processing.

Superior Static Mixing for High-Temperature Applications

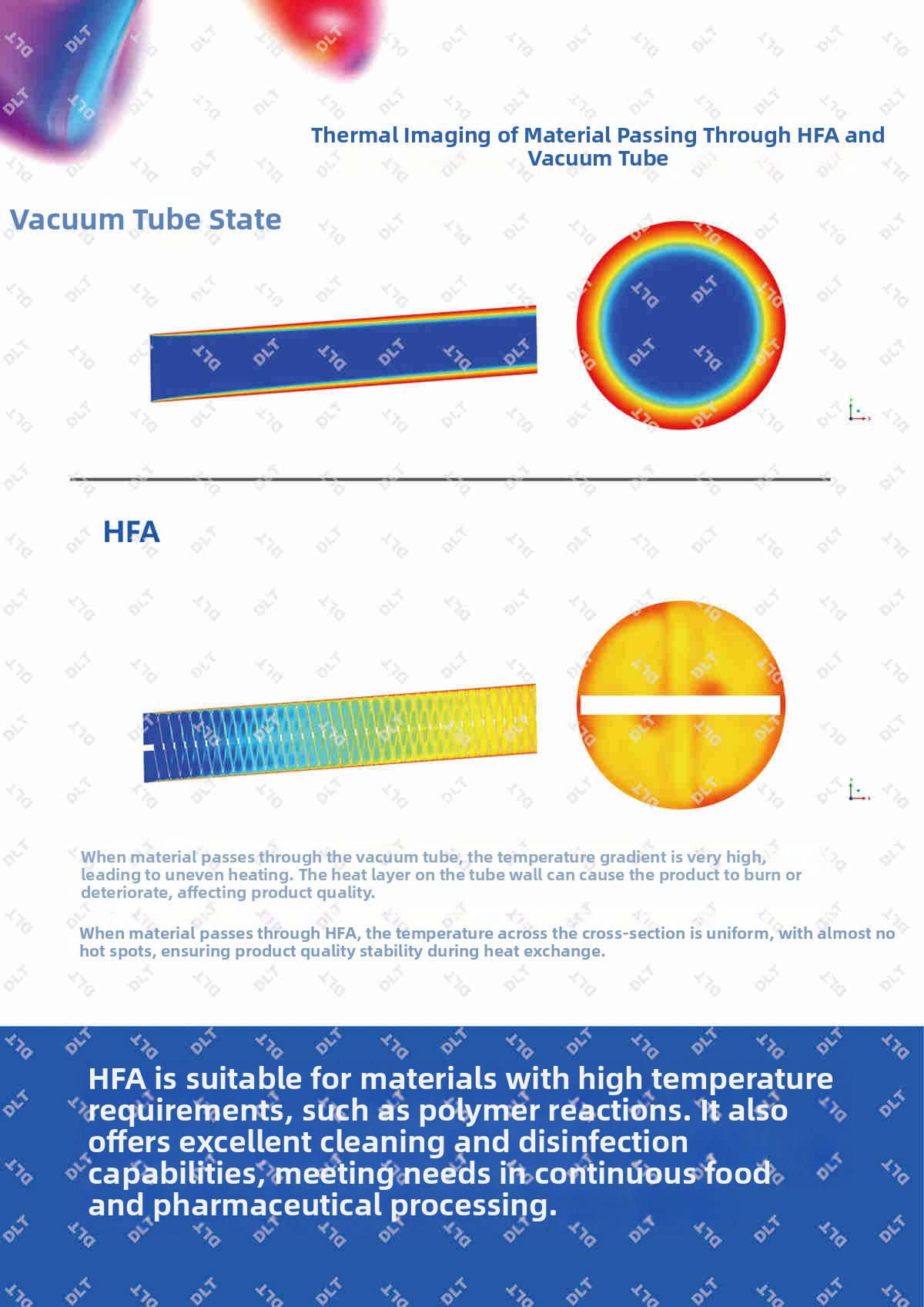

The HFA Static Mixer excels in handling materials with stringent temperature requirements, particularly in polymer manufacturing and processing. Our static mixing technology ensures uniform heat distribution and consistent material processing, enabling optimal polymer reactions and superior product quality. The system's innovative design provides excellent cleaning and disinfection capabilities, meeting the rigorous hygiene standards required in continuous food processing and pharmaceutical manufacturing.

Advanced Degassing Technology for Polymer Processing

Molecular weight and distribution significantly impact polymer performance characteristics. Unreacted monomers, oligomers, solvents, and other small molecules can compromise product quality and fail to meet customer performance requirements or environmental standards. The HFA Static Mixer addresses these challenges through integrated degassing technology that efficiently removes volatile compounds during polymer production.

Our degassing technology works by rapidly and uniformly heating polymers to specific temperatures using high-viscosity fluid heat exchangers combined with advanced static mixing elements. The system facilitates the escape of volatile compounds through optimized agent addition and superior dispersion mechanics. The HFA Static Mixer ensures even polymer distribution within the degasser, significantly increasing surface area while reducing interface resistance for exceptionally efficient degassing operations.

Customized Degassing Solutions

Based on specific polymer characteristics and extensive degassing experience, the HFA system offers single or multi-stage degassing processes tailored to individual production requirements. The core equipment integrates heat exchangers with specialized mixing elements, high-efficiency static mixers, and optimized distributors designed to enhance final product quality while reducing operational costs.

Key Features and Benefits

High-Temperature Capability: Ideal for polymer reactions and processes requiring elevated temperatures

Superior Mixing Performance: Advanced static mixing elements ensure uniform material distribution and consistent processing

Efficient Degassing Technology: Effectively removes unreacted monomers, solvents, and volatile compounds

Enhanced Cleaning Capabilities: Designed for easy cleaning and disinfection, perfect for food and pharmaceutical applications

Customizable Configurations: Single or multi-stage degassing processes tailored to specific material requirements

Improved Product Quality: Consistent molecular weight distribution and superior polymer performance

Reduced Operational Costs: Efficient design lowers energy consumption and maintenance requirements

Environmental Compliance: Helps meet stringent environmental standards by effectively removing harmful volatiles

Industry Applications

The HFA Static Mixer serves numerous critical applications across various industries:

Polymer production and reaction processes

Pharmaceutical manufacturing requiring strict hygiene standards

Food processing with continuous cleaning requirements

Chemical processing with high-temperature needs

Environmental technology applications meeting compliance standards

Technical Excellence

The HFA Static Mixer incorporates the latest advancements in static mixing technology, featuring specially designed mixing elements that create optimal flow patterns for both heating and degassing operations. The system's innovative design ensures maximum surface area exposure and minimal interface resistance, facilitating efficient removal of volatile compounds while maintaining precise temperature control throughout the process.

For manufacturers seeking advanced static mixing solutions that combine high-temperature capability, efficient degassing technology, and superior mixing performance, the HFA Static Mixer delivers unmatched reliability and results. Experience the future of industrial processing with our state-of-the-art static mixer technology, designed to meet the most demanding requirements in polymer production, food processing, and pharmaceutical manufacturing.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...