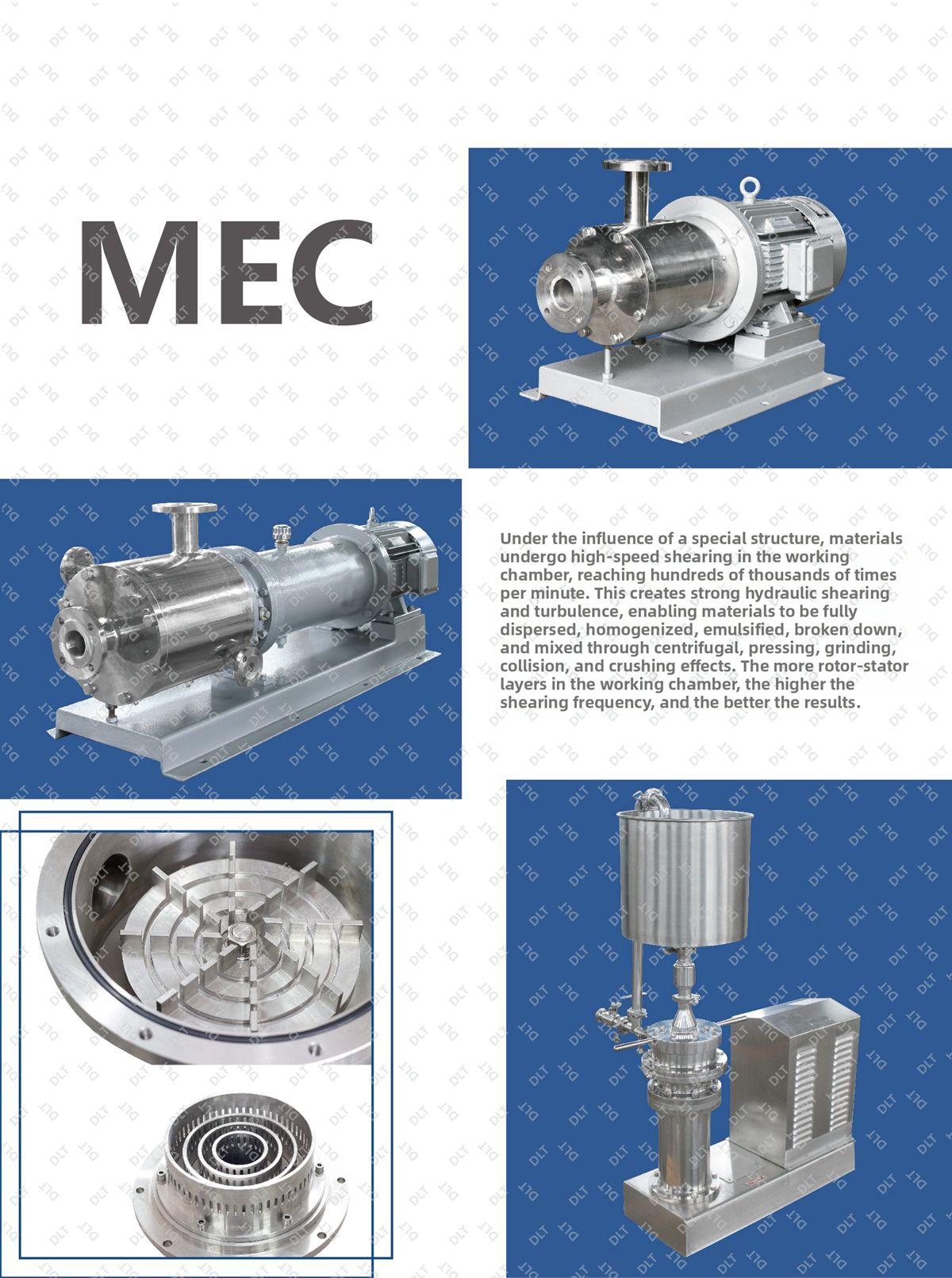

MEC Inline Mixer

The MEC Inline Mixer represents the pinnacle of inline mixing innovation, delivering unprecedented mixing performance through its advanced ultra-high shear technology. This superior inline static mixer utilizes a specialized multi-layer rotor-stator design that subjects materials to hundreds of thousands of high-speed shear actions per minute, achieving exceptional dispersion, homogenization, and particle size reduction in a single continuous process.

Revolutionary Ultra-High Shear Technology

The MEC Inline Mixer features an innovative working chamber design that generates extreme mechanical forces through precisely engineered rotating and stationary elements. This advanced inline mixer technology creates intense hydraulic shear and powerful turbulence, enabling comprehensive material processing that meets the most demanding industrial requirements.

Advanced Mixing Mechanism

The MEC's cutting-edge design delivers superior processing through multiple simultaneous actions:

Ultra-High Frequency Shearing: Hundreds of thousands of shear actions per minute

Intensive Hydraulic Shear: Powerful liquid shear forces for optimal material processing

Multi-Directional Turbulence: Complex flow patterns ensuring complete homogenization

Combined Mechanical Actions: Simultaneous centrifugal, compression, impact, and grinding forces

Progressive Refinement: Multi-stage processing for increasingly finer results

Superior Processing Performance

The MEC Inline Mixer achieves remarkable results through its unique mechanical action:

Complete Dispersion: Perfect particle distribution and material integration

Excellent Homogenization: Uniform consistency and texture throughout processed materials

Precision Emulsification: Stable emulsion creation for challenging liquid-liquid systems

Efficient Particle Reduction: Effective breaking and fine grinding capabilities

Thorough Mixing: Comprehensive material blending and incorporation

Scalable Performance Technology

The MEC's innovative design features multiple rotor-stator layers that directly impact performance:

Increased Shear Frequency: More layers generate higher shear actions per minute

Enhanced Processing Efficiency: Additional stages improve overall mixing effectiveness

Superior End Results: Greater number of layers delivers finer particle size distribution

Optimized Performance: Configurable layers for specific application requirements

Key Features and Benefits

Ultra-High Shear Capacity: Hundreds of thousands of shear actions per minute

Multi-Layer Design: Configurable rotor-stator layers for optimized performance

Continuous Operation: Inline mixing capability supports uninterrupted production

Versatile Application: Suitable for various viscosity ranges and material types

High-Efficiency Processing: Rapid results reduce processing time and energy consumption

Easy Integration: Compact design allows simple installation into existing lines

Low Maintenance: Robust construction with minimal operational requirements

Industrial Applications

The MEC Inline Mixer excels in demanding applications including:

Pharmaceutical nanoemulsions and suspensions

High-end cosmetic and personal care products

Advanced coating and ink formulations

Food and beverage homogenization

Chemical processing requiring ultra-fine dispersion

Nanomaterial processing and dispersion

Adhesive and sealant manufacturing

Technical Advantages

This premium inline static mixer offers significant benefits:

Unmatched Shear Intensity: Highest shear frequency available in inline mixing technology

Superior Product Quality: Exceptional fineness and stability characteristics

Energy Efficiency: Optimized design reduces power consumption while maximizing results

Process Consistency: Reliable and repeatable performance across production batches

Scalable Performance: Adjustable shear intensity through configurable layers

Sanitary Construction: Available in pharmaceutical and food-grade designs

Performance Excellence

The MEC Inline Mixer delivers unprecedented results through its unique combination of ultra-high frequency shearing and advanced mechanical actions. The system's ability to generate simultaneous shear, impact, and compressive forces ensures complete material processing in a single pass, making it ideal for applications requiring ultra-fine dispersion, stable emulsification, or exceptional product homogeneity.

Why Choose MEC Inline Mixer?

The MEC stands out in the inline mixer market through its:

Ultimate Shear Performance: Unmatched shear frequency and processing capabilities

Superior Results: Exceptional product quality and processing consistency

Technical Innovation: Advanced multi-layer engineering for challenging applications

Proven Reliability: Robust construction for continuous industrial operation

Comprehensive Support: Complete technical assistance and service packages

For manufacturers seeking the ultimate in inline mixing technology for demanding dispersion and emulsification applications, the MEC Inline Mixer provides the perfect solution that combines mechanical excellence with superior processing performance. Experience the future of high-shear mixing technology with the MEC – where innovation meets unparalleled performance excellence.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...