MHD Inline Mixer

The MHD Inline Mixer represents cutting-edge inline mixing technology specifically engineered for the dairy and beverage sector. This advanced inline static mixer delivers exceptional performance in dissolving powders, sugars, and gums through its innovative high-speed mixing system, offering unparalleled efficiency and reliability in continuous processing applications.

Advanced Mixing Technology

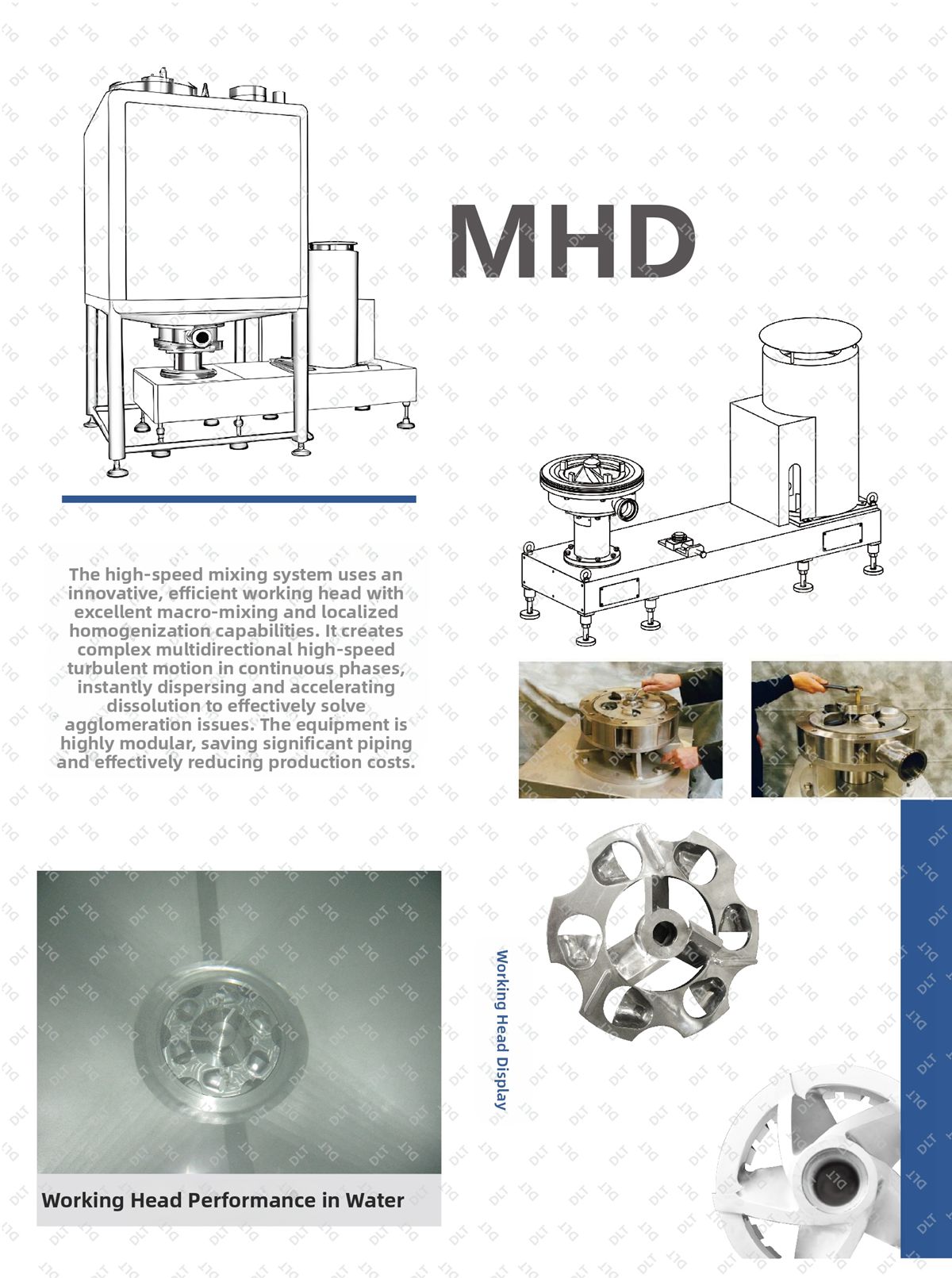

The MHD Inline Mixer features a revolutionary efficient working head design that provides excellent macro mixing capabilities combined with highly efficient local homogenization. Operating within the continuous phase, it creates multi-dimensional, complex high-speed turbulent flow patterns that enable instant dispersion, accelerated dissolution, and effective elimination of agglomeration issues.

Key Features and Benefits

High-Capacity Processing: Continuous inline mixing with flow rates up to 50 m³/h and maximum powder dosing capacity of 8 tons/hour

Exceptional Powder Dispersion: Square tank design creates strong turbulence for rapid powder incorporation into liquids

Instant Homogenization: Bottom-mounted turbine shear head ensures immediate and uniform dispersion

Belt Drive System: Compact bottom installation effectively reduces overall equipment height

Modular Construction: Simplified installation and maintenance with highly integrated module design

High-Viscosity Capability: Custom models handle viscosities up to 10,000 cP

CIP Compatibility: Full clean-in-place capability for optimal hygiene and efficiency

Reduced Infrastructure: Highly modular integration significantly reduces piping requirements and production costs

Industrial Applications

The MHD Inline Mixer is specifically designed for:

Dairy product processing and formulation

Beverage production and powder dissolution

Sugar dissolving applications

Gum and colloid dissolution

Powder-liquid mixing and dispersion

Continuous processing lines

High-capacity production environments

Technical Specifications

Flow Capacity: Up to 50 m³/hour

Powder Handling: Maximum 8 tons/hour

Viscosity Range: Up to 10,000 cP (custom models)

Drive System: Efficient belt transmission

Installation: Bottom-mounted for reduced height

Construction: Square tank with turbine shear head

Hygiene: Full CIP capability

Design: Modular structure for easy installation

Performance Advantages

This advanced inline static mixer offers significant benefits:

Rapid Dissolution: High-speed turbulent flow ensures instant powder dispersion

Efficient Operation: Reduced energy consumption through optimized design

Space Saving: Compact modular design minimizes footprint

Easy Maintenance: Simple access and cleaning procedures

Process Flexibility: Adaptable to various product types and viscosities

Quality Consistency: Uniform mixing results across all production batches

Why Choose MHD Inline Mixer?

The MHD stands out in inline mixing technology through its:

Industry-Specific Design: Optimized for dairy and beverage applications

High Capacity: Unmatched powder handling and processing capabilities

Operational Efficiency: Reduced installation and maintenance costs

Hygienic Design: Full CIP compliance for food-grade applications

Proven Reliability: Robust construction for continuous operation

Technical Support: Comprehensive service and maintenance packages

For dairy and beverage manufacturers seeking superior inline mixing solutions, the MHD Inline Mixer provides the perfect combination of high-performance processing, operational efficiency, and hygienic design. Experience the future of continuous mixing technology with the MHD – where innovation meets practical industrial application excellence.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...