DXM High Shear Mixer

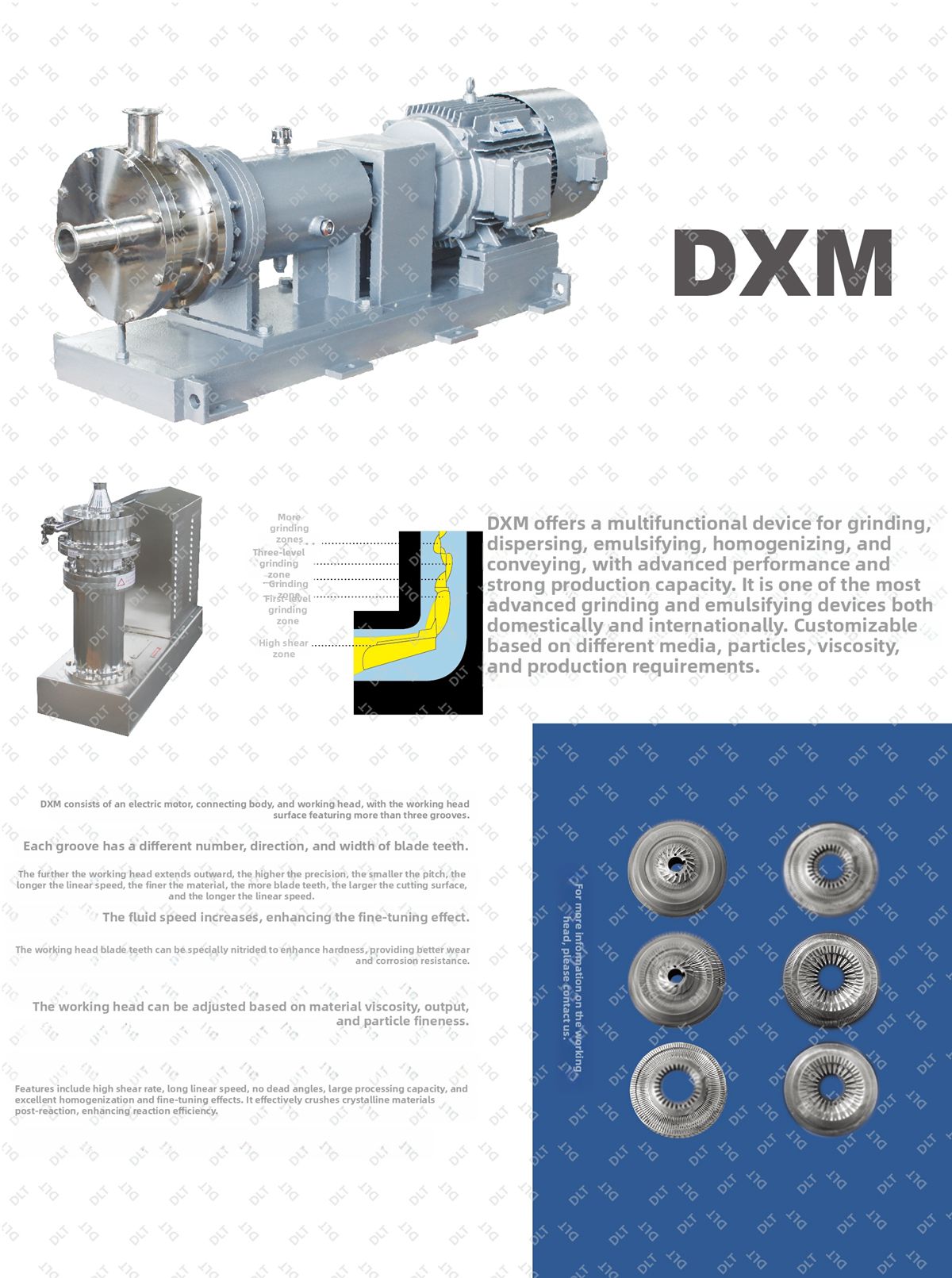

1. Overview and Core Functionality

The DXM High Shear Mixer is a high-efficiency industrial mixer engineered for exceptional particle reduction, emulsification, homogenization, and dispersion. Combining robust performance with advanced mixing technology, this High Shear Mixer is ideal for a wide range of applications requiring ultra-fine grinding and uniform product consistency.

2. Advanced Working Head Design

Comprising a motor, connection assembly, and a uniquely designed working head, the DXM mixer stands out with its multi-grooved rotor-stator structure. The working head features more than three grooves, each with varying tooth count, direction, and width. As the material moves outward through each stage, the working head offers increasing precision—higher tooth density, smaller gap sizes, greater linear speed, and enhanced shear surface area. This results in faster fluid velocity and superior refining效果, ensuring particles are ground finer and mixtures more homogeneous.

3. Customization and Material Adaptability

The teeth of the working head can undergo specialized nitriding treatment to improve hardness, wear resistance, and corrosion resistance. The head is adjustable to accommodate material viscosity, production volume, and desired particle size, offering high shear rates, extended linear velocity, dead-zone-free operation, and large processing capacity. It is particularly effective in refining post-reaction crystalline materials, promoting more complete chemical reactions.

4. Multi-Functional Processing Capabilities

The DXM High Shear Mixer integrates multiple functions—including crushing, dispersing, emulsifying, homogenizing, grinding, crushing, and pumping—into one versatile unit. It is recognized as one of the most advanced grinding and emulsification systems available worldwide and can be customized based on specific process requirements, media properties, particle size, and viscosity.

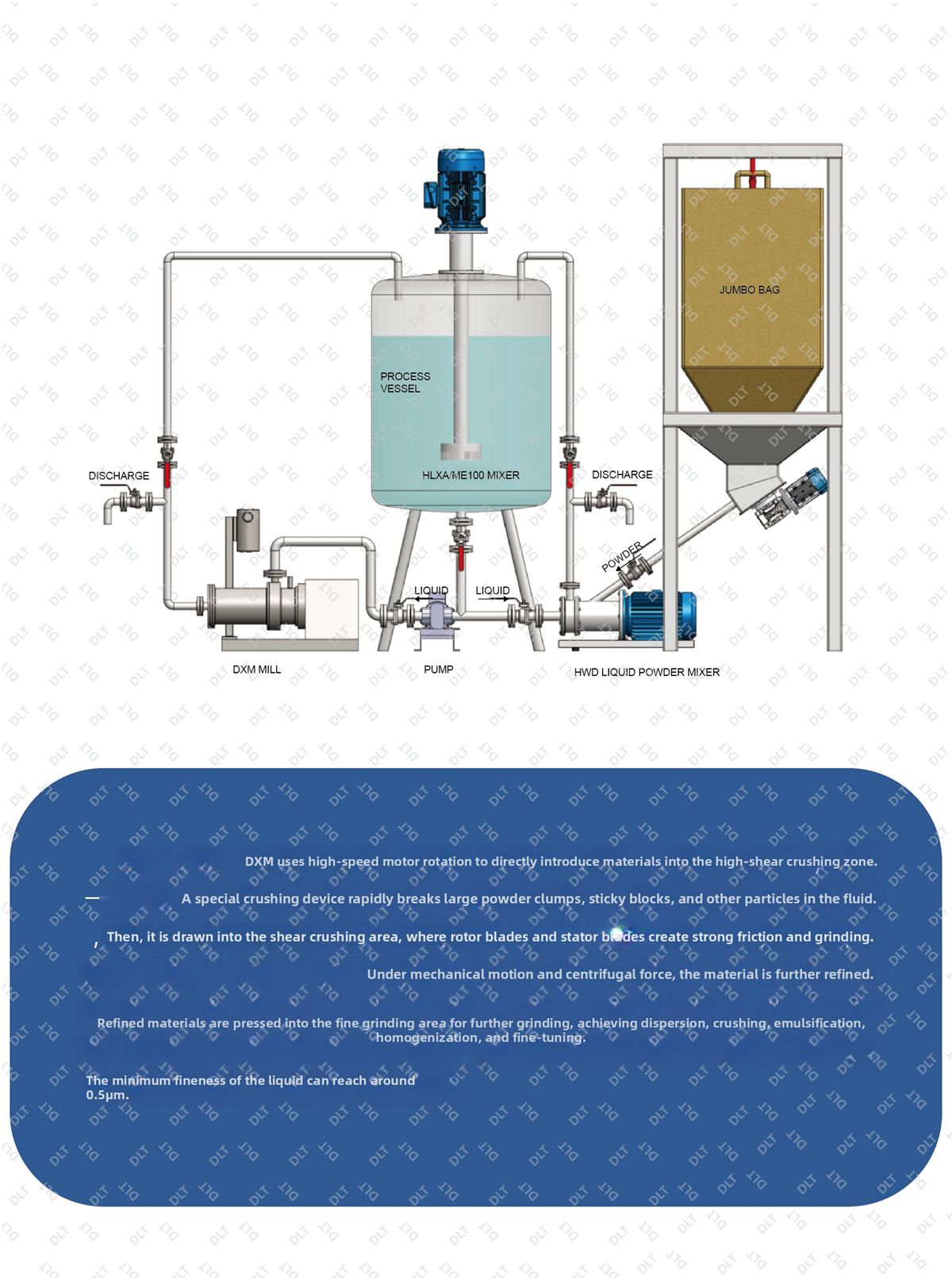

5. Operational Mechanism and Refinement Process

In operation, the motor drives high-speed rotation, drawing material from the inlet directly into the high-shear crushing zone. A specialized grinding mechanism quickly breaks down large powder agglomerates, sticky lumps, and particle clusters within the fluid. The material then enters the shear grinding zone, where the narrow clearance between the rotating and stationary blades generates intense cutting, friction, and grinding actions. Under mechanical force and centrifugal pressure, the refined material is forced into the precision grinding zone for further processing, achieving molecular chain rupture, particle fragmentation, and droplet breakup. This process ensures thorough dispersion, crushing, emulsification, homogenization, and refinement, with final particle sizes as small as 0.5 microns.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...