DMX High Shear Mixer

The DMX High Shear Mixer represents the pinnacle of industrial mixing technology, featuring an innovative four-stage processing system that delivers unparalleled particle reduction, emulsification, and homogenization performance. This premium High Shear Mixer combines precision engineering with advanced fluid dynamics to achieve exceptional results in the most demanding processing applications.

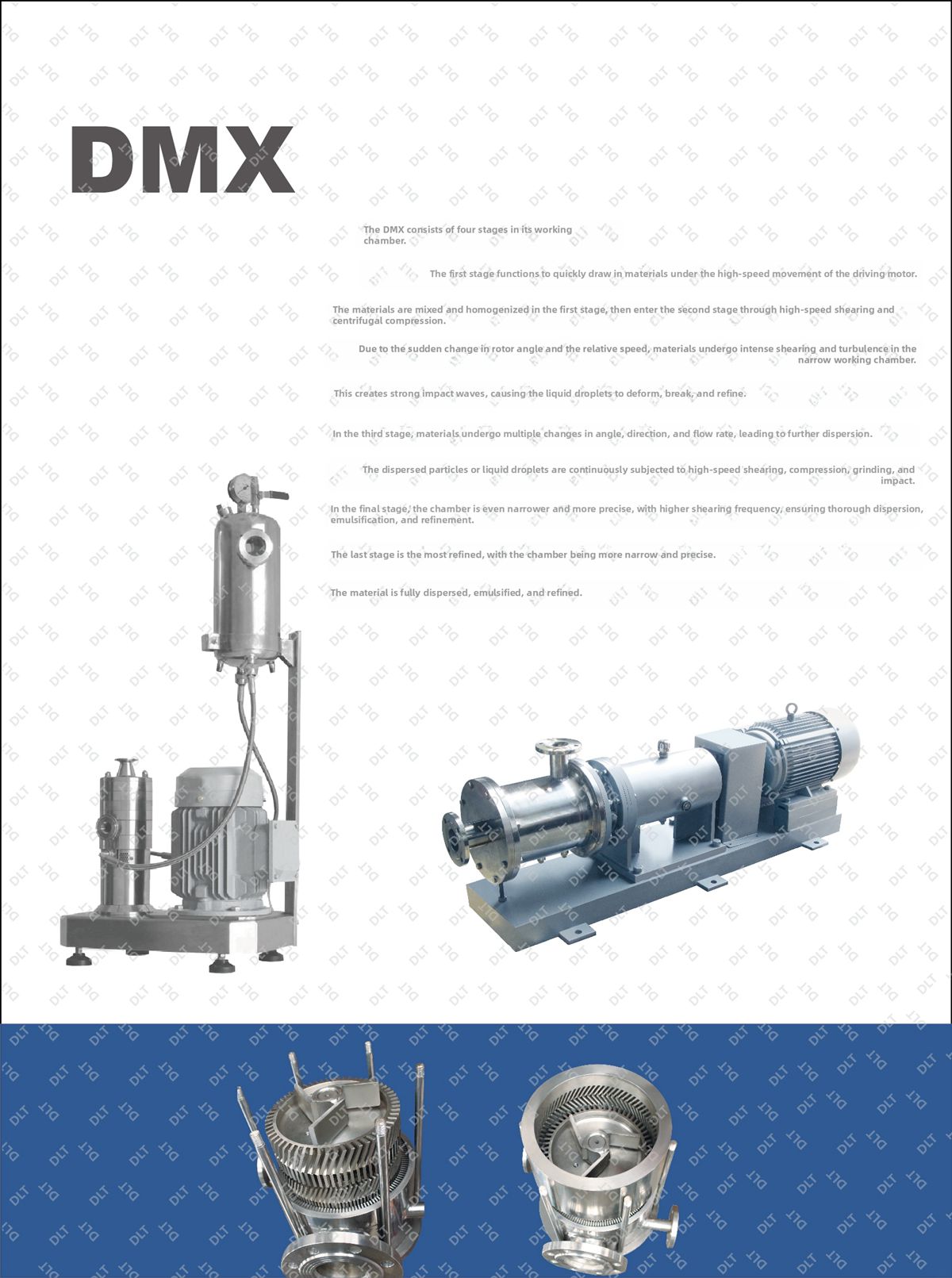

Revolutionary 4-Stage Processing Technology

Stage 1: High-Speed Intake & Primary Mixing

Rapid Material Ingestion: Powerful motor-driven intake system ensures efficient material handling

Initial Homogenization: Primary mixing and blending in the first processing chamber

Centrifugal Acceleration: Advanced centrifugal forces prepare materials for subsequent stages

High-Shear Pre-treatment: Initial size reduction and dispersion begins immediately

Stage 2: Intensive Shear & Turbulence Generation

Instant Direction Changes: Rapid rotor-stator angle alterations create optimal processing conditions

Extreme Liquid Shear: Intensive mechanical action in confined processing spaces

Shock Wave Production: Powerful impact waves cause immediate droplet deformation

Turbulent Flow Creation: Advanced fluid dynamics ensure complete particle interaction

Primary Particle Reduction: Initial breakdown and size reduction occurs

Stage 3: Multi-Directional Precision Refinement

Repeated Flow Alterations: Multiple changes in angle, direction, and velocity

Advanced Hydrodynamic Effects: Optimized fluid mechanics enhance processing efficiency

Combined Mechanical Forces: Simultaneous shear, compression, and impact action

Progressive Size Reduction: Continuous refinement and particle optimization

Enhanced Dispersion: Improved distribution and homogeneity throughout the mixture

Stage 4: Ultimate Precision Processing

Micro-Processing Chamber: Ultra-confined space for final refinement stage

Maximum Shear Frequency: Highest level of mechanical action achieved

Final Emulsification: Complete droplet dispersion and stabilization

Particle Optimization: Achievement of ultimate fineness and uniform distribution

Quality Assurance: Consistent, reproducible results batch after batch

Key Features & Benefits

Four-Stage Processing: Comprehensive material treatment in single-pass operation

Superior Efficiency: Reduced processing time through optimized mechanical action

Exceptional Particle Reduction: Sub-micron and nanometer scale achievement

Enhanced Product Stability: Superior emulsion quality and extended shelf life

Energy Optimization: Efficient power utilization across all processing stages

Continuous Operation: Uninterrupted production capability for high-volume processing

Low Maintenance Design: Robust construction ensures reliable long-term performance

Technical Advantages

The DMX High Shear Mixer delivers unmatched processing benefits:

Complete Material Treatment: Full processing from intake to final refinement

Improved Product Quality: Consistent particle size distribution and enhanced characteristics

Reduced Operating Costs: Lower energy consumption and maintenance requirements

Versatile Application Range: Suitable for various viscosity levels and material types

Scalable Performance: Consistent results from laboratory to full production scale

Temperature Control Options: Available cooling/heating jackets for sensitive materials

Industrial Applications

Pharmaceutical nanoemulsions and suspension preparations

Cosmetic and personal care product manufacturing

Food and beverage processing and homogenization

Chemical and petrochemical applications

Paint, coating, and ink production systems

Nanomaterial dispersion and advanced processing

Specialty chemical and material synthesis

Performance Excellence

The DMX High Shear Mixer achieves extraordinary results through its advanced processing approach:

Ultimate Particle Reduction: Down to nanometer scale precision

Superior Emulsion Quality: Exceptional stability and performance characteristics

Rapid Processing Times: Significant reduction in production cycles

Perfect Homogeneity: Consistent results across all production batches

Enhanced Product Performance: Improved end-product characteristics and functionality

Why Choose DMX High Shear Mixer?

Advanced Engineering: Innovative four-stage processing technology

Proven Performance: Demonstrated excellence in demanding applications

Premium Construction: High-quality materials ensure durability and reliability

Comprehensive Support: Complete technical service and maintenance programs

Customizable Solutions: Tailored to specific process requirements and applications

Global Compliance: Meets international quality and safety standards

For manufacturers seeking the ultimate in mixing technology, the DMX High Shear Mixer delivers exceptional performance through its advanced four-stage processing system. Experience the future of industrial mixing with the DMX series – where precision engineering meets superior results in particle reduction, emulsification, and product quality optimization.

Related Products

MORE

-

SY Static M…

The SY Static Mixer represents a significant advancement in motionless mixing technology, engineered to deliver exceptional performance with remarkable efficiency. Unlike conventional mixers, the SY features a unique construction consisting of a series of …

-

SX Static M…

The SX Static Mixer represents a specialized advancement in static mixing technology, specifically engineered to address the challenges of medium to high viscosity fluid processing. This unique mixer design features an innovative arrangement of intersectin…

-

SV Static M…

The SV Static Mixer represents a sophisticated advancement in static mixing technology, featuring a unique cylindrical structure composed of specially designed corrugated plates. This innovative configuration creates exceptional mixing performance across a…

-

5

2025-9

Static Mixer: Superior Gas-Liquid Mixing Technology by Hera Industrial

The SV Static Mixer is a highly efficient static mixer engineered specifically for optimizing gas-liquid mixing processes. By eliminating uneven stratification and ensuring precise homogenization, this mixer delivers exceptional performance in applications…Read more...

-

5

2025-9

Static Mixer by Hera Industrial

Overview: High-Efficiency Static Mixing SolutionHera Industrial’s Static Mixer delivers precision mixing performance across a wide range of industrial applications. Unlike conventional High Speed Mixer systems, this static solution operates with no moving…Read more...

-

5

2025-9

Static Mixers: Applications, Benefits, and Uses Across Industries

Static mixers, also known as motionless mixers, are highly efficient inline mixing devices used across a wide range of industries for blending, reacting, heating, cooling, and dispersing fluids—without any moving parts. Their simple yet innovative design …Read more...

-

29

2025-8

Innovative Static Mixing Technology: Revolutionizing Industrial Fluid Processing

Static mixers have reshaped modern industrial operations by offering a sophisticated yet simple solution for fluid blending, reaction, and dispersion – all without any moving parts. These highly adaptable devices are engineered to meet the rigorous deman…Read more...